OUR CAPABILITIES

From concept to reliable production, we provide end-to-end die-casting mold services backed by advanced CAD/CAM and high-precision machining.

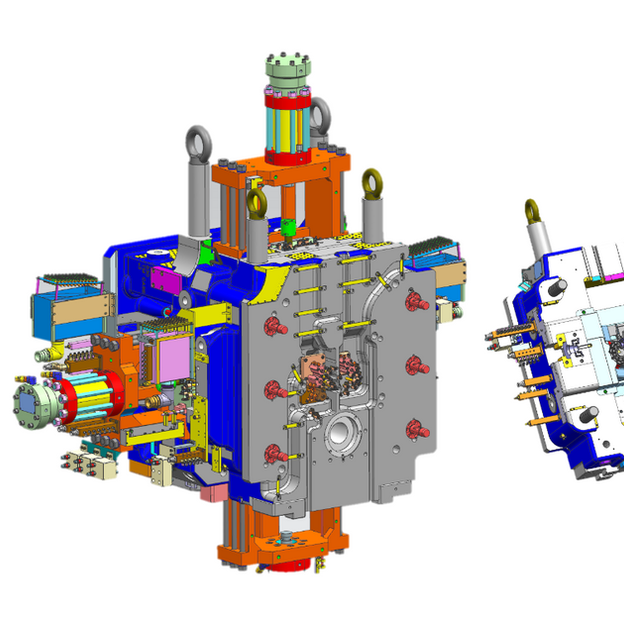

New Die-Casting Mold Assembly

Design and manufacture of new molds ranging from 350 to 2500 tons, including specialized solutions for automotive systems, machinery, and industrial components.

Design for manufacturability and durability

Tight tolerances and high dimensional stability

Optimized cooling and cycle time efficiency

Tool trials, validation, and production ramp support

Mold Re-engineering & Modification

Comprehensive upgrades for existing molds to extend service life and improve output quality.

Gate, runner, and cooling optimization

Dimensional corrections and wear-area reinforcement

Preventive rebuilds and component replacement

Troubleshooting casting defects and improving yield

Specialized Component Manufacturing

Production of high-precision mold parts, including:

Main Core • Insert Core • Machine Sleeves • Sleeve Bushings • Plunger Tips • Die-Casting Sleeves

Material selection for wear and heat resistance

Precision finishing for sealing, fit, and thermal performance

Rapid turnarounds for critical spares

End-to-End Technical Solutions

We support the full lifecycle: initial design → production → testing → maintenance, plus ongoing technical support.

CAD/CAM engineering collaboration

Prototyping and pilot runs

Preventive maintenance schedules

On-site support and quick-response service

FEATURED WORK

Building Quality

Into Every Project

Home

About

Contact

601-42 Songsanpo-ro, Hwaseong-si,

Gyeonggi-do, Republic of Korea

Tel +82-31-496-9809 • Fax +82-31-496-9806

© 2025 SHINWOO TECH